Earth To Earth Rocketry + Hyperloop: Earth Before Mars

— Kekius Maximus (@elonmusk) May 21, 2025

SpaceX has significantly reduced the cost per kilogram of payload to orbit through innovations in rocket design, particularly with the Falcon 9, Falcon Heavy, and Starship. Below is an analysis of how these costs have evolved, the reduction ratios, and the key factors driving these changes, based on available data up to 2025.

Cost per Kilogram to Low Earth Orbit (LEO) Over Time

- Historical Context (Pre-SpaceX, Space Shuttle Era):

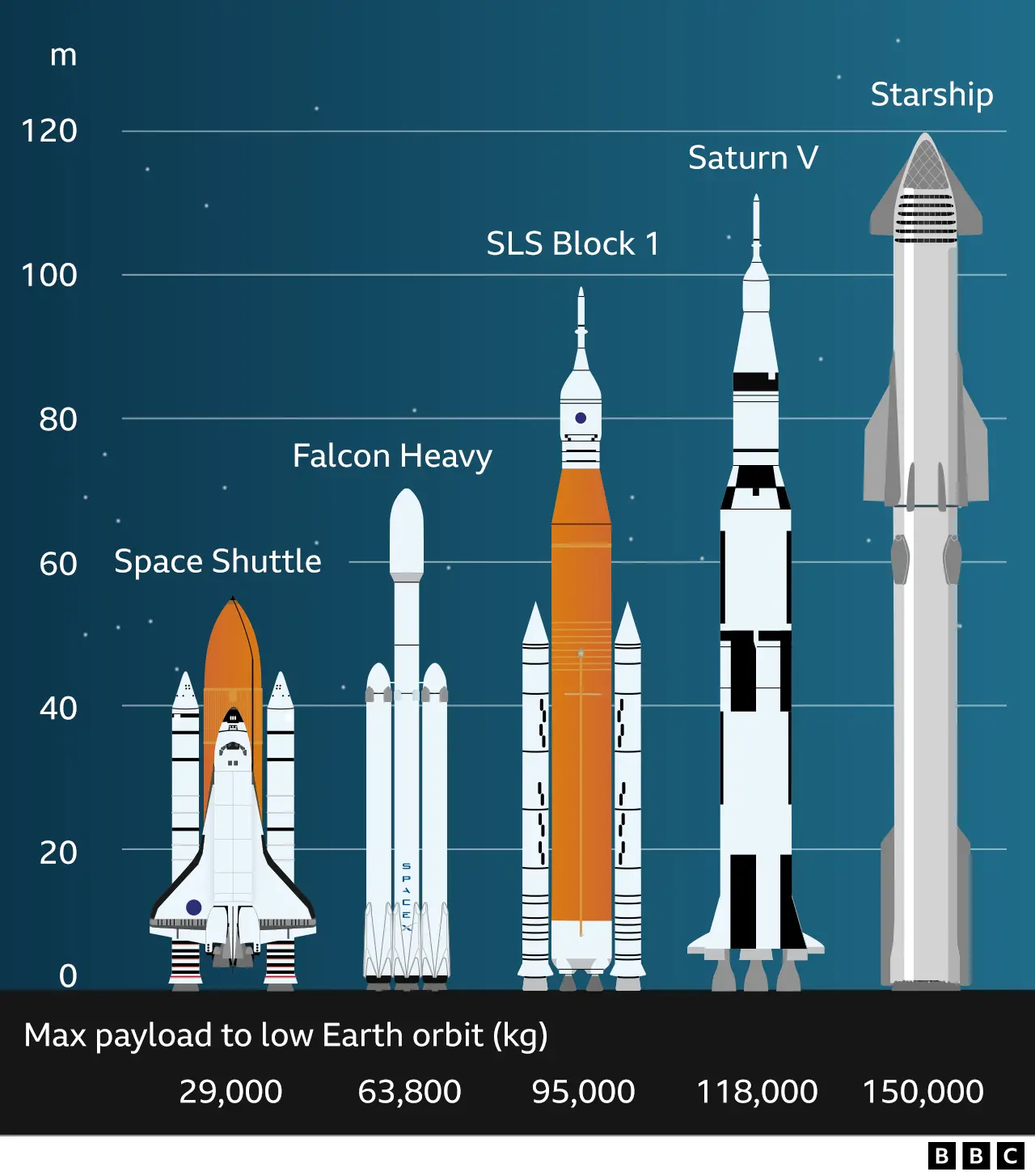

- NASA Space Shuttle (1981–2011): The cost to launch a payload to LEO was approximately $54,500 per kg, based on an average launch cost of $1.5 billion for a 27,500 kg payload.

- This high cost was due to the shuttle's complex design, limited reusability (only solid rocket boosters and the orbiter were reused, with high refurbishment costs), and low launch cadence.

- Falcon 9 (2010–Present):

- Initial Cost (2010–2015): Early Falcon 9 launches cost around $62 million for a 22,800 kg payload to LEO, equating to approximately $2,720 per kg. This represented a ~20-fold reduction compared to the Space Shuttle ($54,500/kg ÷ $2,720/kg ≈ 20).

- Post-Reusability (2015–2025): With the introduction of reusable first-stage boosters (first successful landing in December 2015), costs dropped further. By 2022, Falcon 9 launches were priced at $67 million (adjusted for inflation), with some estimates suggesting internal costs as low as $28 million per launch for Starlink missions, translating to ~$1,600–$2,000 per kg for a reusable Falcon 9 with a 16,250–22,800 kg payload.

- Reduction Ratio: Compared to the Space Shuttle, Falcon 9 reduced costs by a factor of ~27–34 ($54,500 ÷ $1,600–$2,000). Compared to early Falcon 9, reusability lowered costs by ~1.4–1.7 times ($2,720 ÷ $1,600–$2,000).

- Falcon Heavy (2018–Present):

- Cost and Capacity: Falcon Heavy, with a payload capacity of up to 63,800 kg to LEO, has a list price of ~$90 million, equating to ~$1,400 per kg.

- Reduction Ratio: Compared to the Space Shuttle, Falcon Heavy reduced costs by ~39 times ($54,500 ÷ $1,400). Compared to early Falcon 9, the cost per kg dropped by ~1.9 times ($2,720 ÷ $1,400).

- Starship (Projected, 2025–Future):

- Current Estimates (2025): Starship, with a reusable payload capacity of 100–150 tons (100,000–150,000 kg) to LEO, is estimated to have a build cost of ~$90 million, with SpaceX likely charging customers ~$180 million initially. For a 150-ton payload, this yields ~$1,200 per kg for single-use launches. With partial reusability (6 flights), costs could drop to $78–$94 per kg, and with high reusability (20–70 flights), projections suggest $13–$32 per kg.

- Aspirational Goals: Elon Musk has stated that Starship’s marginal cost could be as low as $1 million for >100 tons, potentially achieving $10–$20 per kg with full reusability and high launch cadence.

- Reduction Ratio:

- Compared to the Space Shuttle: ~580–4,200 times ($54,500 ÷ $94–$13) with partial to high reusability.

- Compared to Falcon Heavy: ~15–108 times ($1,400 ÷ $94–$13).

- Compared to early Falcon 9: ~29–209 times ($2,720 ÷ $94–$13).

- In the best-case scenario ($10/kg), Starship could achieve a ~5,450-fold reduction compared to the Space Shuttle ($54,500 ÷ $10).

Cost Reduction Trends and Ratios Over the Years

Rocket/System | Year Introduced | Cost per kg (LEO) | Reduction Ratio vs. Space Shuttle | Reduction Ratio vs. Early Falcon 9 |

|---|---|---|---|---|

Space Shuttle | 1981 | $54,500 | - | - |

Falcon 9 (Early) | 2010 | $2,720 | ~20x | - |

Falcon 9 (Reusable) | 2015–2025 | $1,600–$2,000 | ~27–34x | ~1.4–1.7x |

Falcon Heavy | 2018 | $1,400 | ~39x | ~1.9x |

Starship (Initial) | 2025 (est.) | $1,200 | ~45x | ~2.3x |

Starship (6 flights) | 2025–2026 (est.) | $78–$94 | ~580–700x | ~29–35x |

Starship (20–70 flights) | 2027–2028 (est.) | $13–$32 | ~1,700–4,200x | ~85–209x |

Starship (Aspirational) | Future | $10–$20 | ~2,725–5,450x | ~136–272x |

Key Factors Driving Cost Reductions

- Reusability:

- Falcon 9’s reusable first stage (up to 28 flights as of 2025) significantly lowered costs by amortizing the booster’s cost (~70% of the rocket).

- Falcon Heavy leverages three reusable Falcon 9 cores, further spreading costs over larger payloads.

- Starship aims for full reusability (both upper and lower stages), with projections of 20–100 flights per vehicle, drastically reducing per-flight costs.

- Increased Payload Capacity:

- Larger rockets like Falcon Heavy (63,800 kg) and Starship (100,000–150,000 kg) spread fixed costs over more payload mass, reducing cost per kg.

- Starship’s massive capacity allows for economies of scale, especially for megaconstellations like Starlink.

- Simplified Design and Manufacturing:

- SpaceX’s use of Merlin engines (Falcon 9/Heavy) and Raptor engines (Starship) with streamlined production (e.g., 4,000 Raptor engines per year) lowers costs.

- Falcon 9’s iterative design improvements (e.g., Octaweb engine layout, aluminum-lithium tanks) enhanced efficiency.

- Starship’s stainless steel construction reduces material and fabrication costs compared to traditional aerospace materials.

- High Launch Cadence:

- SpaceX’s high launch frequency (91 Falcon 9 launches in 2023, ~150 projected for 2025) spreads fixed infrastructure costs (e.g., launch pads, staff) across more missions.

- Starship’s potential for frequent launches could further drive down costs.

- Private Sector Efficiency:

- Unlike NASA’s bespoke, government-funded programs (e.g., Space Shuttle, SLS), SpaceX’s commercial approach minimizes cost overruns. Falcon 9’s development cost was $390 million, compared to NASA’s estimate of $4 billion for a similar rocket.

- SpaceX’s platform-based strategy (iterative improvements across Falcon 9, Heavy, and Starship) outperforms NASA’s one-off designs.

Yearly Cost Reduction Trends

- 1960s–1980s: Costs ranged from $100,000/kg (early NASA) to $5,400/kg (Saturn V).

- 1980s–2011: Space Shuttle stabilized at ~$54,500/kg due to limited reusability and high maintenance.

- 2010–2015: Falcon 9 reduced costs to $2,720/kg, a ~20x drop from the Shuttle.

- 2015–2022: Reusable Falcon 9 and Falcon Heavy further lowered costs to $1,400–$2,000/kg, a ~27–39x reduction from the Shuttle.

- 2025–Future (Starship): Projections suggest $78–$94/kg with partial reusability (2025–2026), potentially reaching $10–$20/kg by 2027–2040, a 580–5,450x reduction from the Shuttle.

Caveats and Considerations

- Data Variability: Cost estimates vary due to differences in reported prices (sticker price vs. internal costs), payload capacities (expendable vs. reusable), and inflation adjustments.

- Starship Projections: Starship’s costs are speculative as it is not yet fully operational. Actual costs depend on achieving reliable reusability and high launch cadence.

- Market Dynamics: SpaceX’s pricing may not fully reflect cost savings due to market demand and profit margins. For example, Falcon 9’s $6,000/kg for small payloads in rideshare missions is higher than the advertised $2,720/kg.

- External Factors: Competitors like Rocket Lab ($10,000–$20,000/kg) and government programs (e.g., China’s Long March, ~$4,000/kg) provide context, but SpaceX remains the cost leader.

Conclusion

SpaceX’s progression from Falcon 9 to Falcon Heavy to Starship has driven launch costs down dramatically:

- Falcon 9: ~20–34x reduction vs. Space Shuttle ($2,720–$1,600/kg vs. $54,500/kg).

- Falcon Heavy: ~39x reduction ($1,400/kg).

- Starship: Potentially 580–5,450x reduction ($94–$10/kg, projected).

The key drivers are reusability, larger payloads, simplified designs, high launch cadence, and commercial efficiency. While Falcon 9 and Heavy have already transformed the industry, Starship’s full impact depends on achieving its ambitious reusability and cost goals, potentially reaching $10–$20/kg in the future, a ~2,725–5,450x reduction from the Shuttle era.

Earth To Earth Rocketry + Hyperloop: Earth Before Mars