Ok, so, this is a little wild.

— Paramendra Kumar Bhagat (@paramendra) May 30, 2025

A particle accelerator can be simulated in AI to dramatically reduce costs, though with important limitations and trade-offs. Here’s a breakdown:

✅ What AI-Powered Simulation Can Do:

1. Accelerator Design Optimization

AI can:

-

Simulate beam dynamics, magnet configurations, and RF systems.

-

Optimize component layouts without costly prototyping.

-

Reduce design time from years to months.

2. Control Systems and Predictive Maintenance

AI can simulate control systems to:

-

Optimize beam steering and energy usage.

-

Predict component failure before it happens.

-

Automate calibration and tuning.

3. Virtual Experiments

AI can simulate:

-

Particle collisions at various energy levels.

-

Probabilistic particle interactions (based on known physics).

-

Rare event detection scenarios (e.g., Higgs boson events).

4. Training and Education

Virtual labs for physicists and students.

No billion-dollar facility needed to learn how particle accelerators work.

❌ What AI Simulation Cannot Fully Replace (Yet):

1. Empirical Data

-

AI models are only as good as the data they are trained on.

-

Discovering new physics (e.g., dark matter candidates, supersymmetry) requires real experimental data.

-

Quantum phenomena often involve unpredictable outcomes AI cannot fully model.

2. Hardware-Specific Constraints

-

Simulations can’t replicate material stresses, thermal effects, vacuum degradation, or superconducting magnet issues at a deep physical level.

-

Real-world prototypes are still needed to validate AI models.

3. Extreme Conditions

-

Simulating the exact plasma behavior, quantum chromodynamics, or gravitational interactions at femtometer scales still pushes the boundaries of computational capacity.

🌐 Real-World Examples of AI in Particle Physics

-

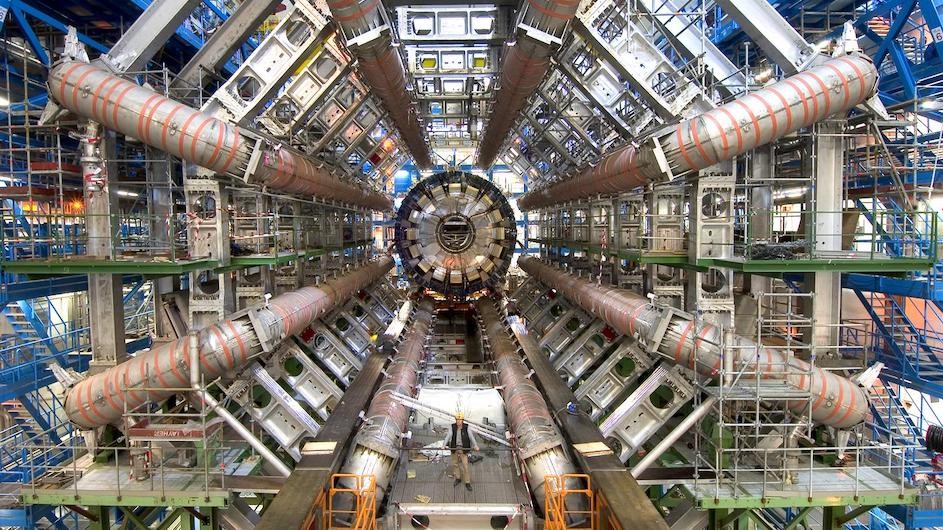

CERN uses ML/AI to filter collision data at the LHC — it processes millions of events per second.

-

SLAC and Fermilab are using reinforcement learning to optimize accelerator tuning.

-

Surrogate modeling is being used to replace slow physics simulations with fast AI approximations.

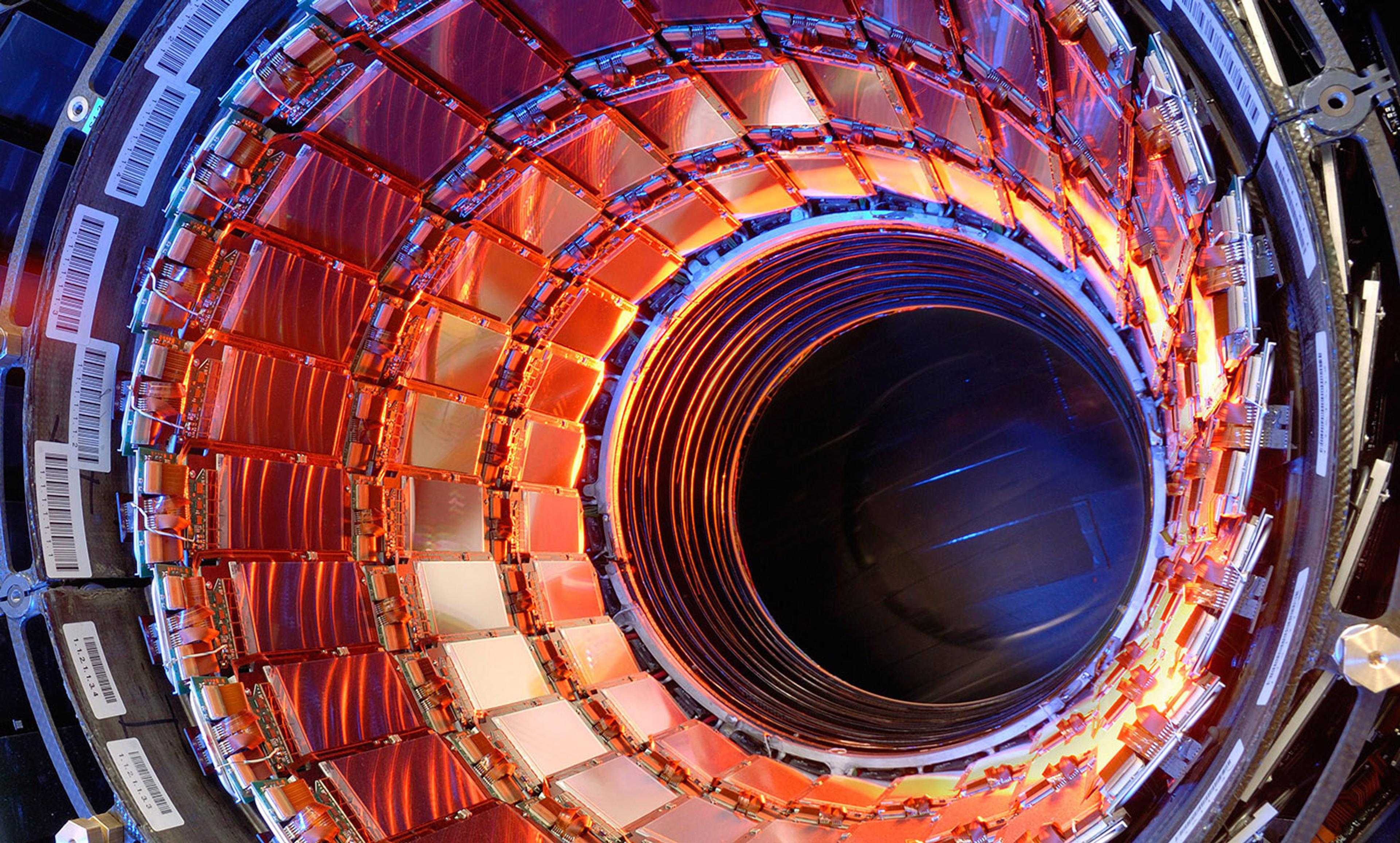

💡 Vision: AI as a Virtual LHC?

Yes — for theory exploration, design, training, and narrowing down experimental targets.

No — for actual discovery of new physical laws or particles, which require empirical validation.

🔁 Hybrid Future

The future of particle physics is hybrid:

-

AI drastically lowers cost, time, and manpower.

-

But physical experiments remain essential for true breakthroughs.

Simulating A Particle Accelerator In AI https://t.co/o4lv4Vcj7j

— Paramendra Kumar Bhagat (@paramendra) May 30, 2025